- home

- company

- services

- products

- Compact and Mobile

- Water treatment and potabilization

- Civil wastewater treatment

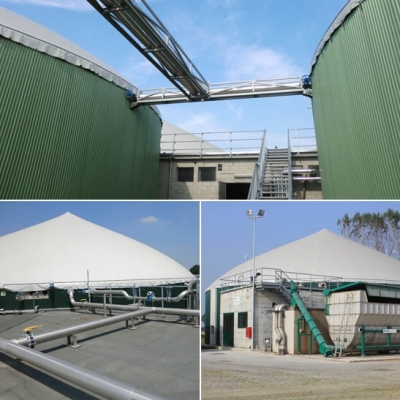

- Biogas and Biomethan

- Stormwater and runoff treatment plants

- Air Deodorization

- Industrial water treatment and water reuse

- Composting Process

- Renewable energy production facilities

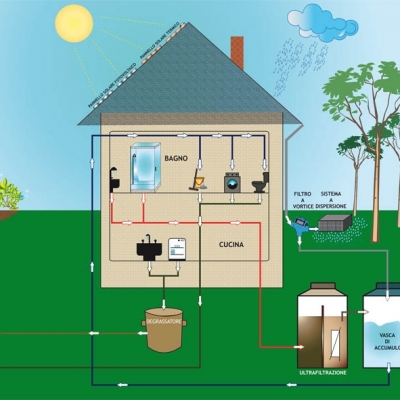

- Rain water reuse and recovery

- Automatic Booster Sets

- Ballast Water Treatment

- intervention sectors

- target

- projects

- shop

- news

- contacts